1, an overview of the

Multi-parameter intelligent well selection and quantity oil sled is specially designed for a series of problems such as complex distribution of oil field gathering and transportation network and inaccurate measurement in zoning. This device adopts the combination of gating device and single well metering device, only using a set of metering device, but can summarize the fluid of multiple Wells and select Wells for metering, reduce production loss, reduce production cost. It is mainly used for oil and gas metering in oil field area, oil and gas metering between oil and gas metering or single well production. It has a wide measuring range and is especially suitable for oil and oil field blocks with low liquid volume, high water cut and high gas content.

2. Solutions

2.1 Overall scheme of system implementation

Multi-parameter intelligent metering system is composed of three parts, namely, skid mounted metering system, PLC automatic control system and software monitoring system.

(1) The metering control system can be connected and measured according to the number of oil pipelines in the station. PLC is used to control the flow of oil well automatic distribution and valve group switch, and the corresponding single well liquid is separated by the liquid-gas separation device, and the gas is measured by the gas flowmeter, and the liquid is measured by the crude oil mass flowmeter after filtration. The moisture content in the liquid can also be measured at the right time by on-line water analyzer.

(2) PLC automatic control system is the core of the whole skid block automatic operation. The automatic well selection of skid block, automatic separation of liquid, liquid and gas separation and measurement, data calculation, storage and other functions are completed by PLC automatic control system.

(3) The software monitoring system is used to monitor the production and operation of the process device. The monitoring system can not only display the running parameters of metering devices in real time, but also connect to the storage management devices in the monitoring center of the management area to realize centralized control and display.

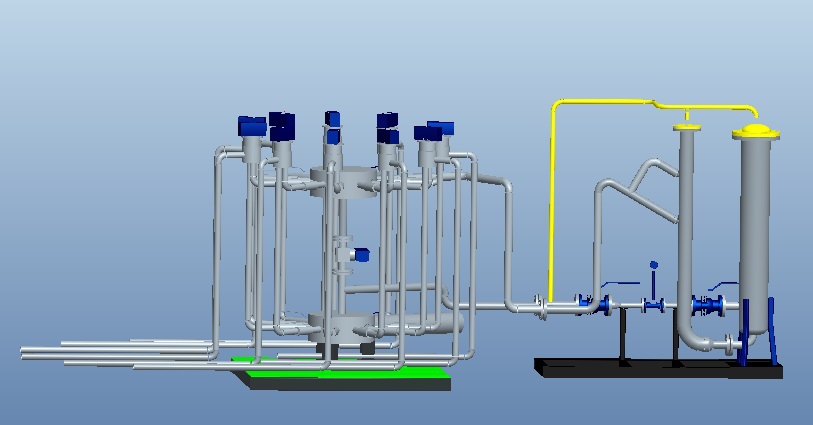

(Multi-parameter intelligent well Selection volume skid)

2.2 System Functions and Features

1) High degree of automation, safe and reliable operation, unattended skid-mounted and other characteristics;

2) The sealing surface of the gating device has the characteristics of corrosion resistance, wear resistance, not easy to scale and so on. At the same time, manual adjustment parts are set to facilitate installation and maintenance, and achieve zero leakage;

3) Small pressure loss, the maximum pressure loss of the whole system is less than 0.1mpa;

4) Equipped with sand removal and filtration device, through regular cleaning, with the change of filter screen to solve pipeline blockage;

5) High measurement accuracy, wide application range. It can realize continuous online measurement of oil, gas and water three-phase fluid in crude oil with different water content.

6) It has a remote communication interface, which can transmit measurement data in real time over a long distance, providing effective conditions for the realization of network management and block management;

7) The metering device is designed with an emergency bypass circuit, which can exceed the pressure relief and prevent pipeline pressure holding;

2.3 Technical specifications of skid mounted metering system

Technical indicators of skid-mounted equipment:

1) Nominal pressure: 0~ 10MPa

2) Nominal diameter: single well inlet pipe diameter DN50~100, sewage pipe: DN50

3) Applicable medium: crude oil, oily sewage, water, steam, etc

4) Medium temperature: 0℃ ~+125℃

5) Liquid viscosity: ≤ 1000Mpa.s (300C)

6) Power supply: 220V/380V 50Hz 3000W

7) Pressure loss: ≤ 0.1mpa

8) Working environment: relative humidity 5% ~ 95%, temperature -20℃- -55℃;

9) Flow range: 0~200 t/d for liquid phase, 0~50000 m3/d for gas phase measurement

10) Measurement accuracy: oil phase ≤0.5%, water content ≤±2%, gas phase ≤1%

11) Output signal: 4~20mA RS485 communication

12) Protection grade: IP65

13) Explosion-proof grade: Exd ⅱ BT4

14) Indoor ambient temperature: 16~ 450C

15) Outdoor ambient temperature: -25.5~ 40.50C

3. Field application cases

Multi-parameter intelligent oil lever with overload resistance, impact resistance, high precision and good stability, high quality, low price, can adapt to the characteristics of various industrial applications, is the crystallization of precision machining, temperature compensation and analog signal processing technology, the main circuit process materials advanced, sealed curing and external complete isolation, It can meet the requirements of moisture-proof, waterproof, explosion-proof, anticorrosion, dustproof and other harsh working conditions. The following is the field application of Shengli Oilfield.

Photos used on site:

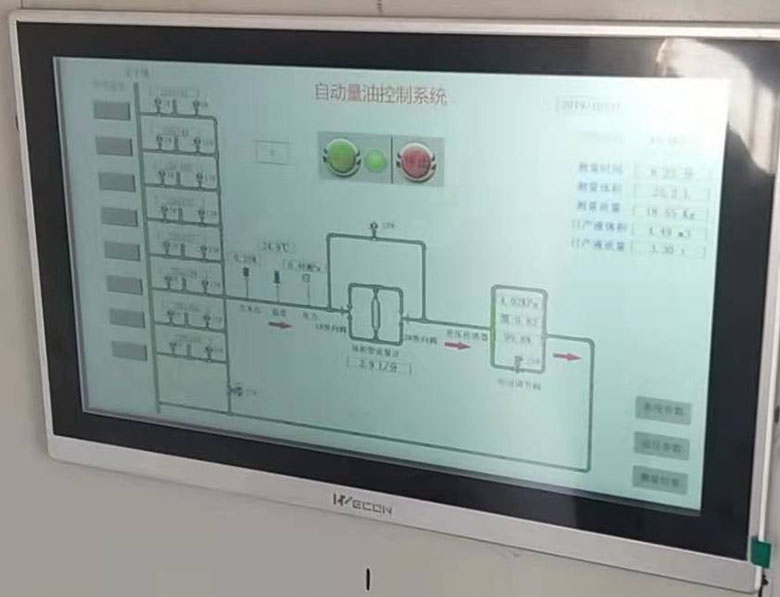

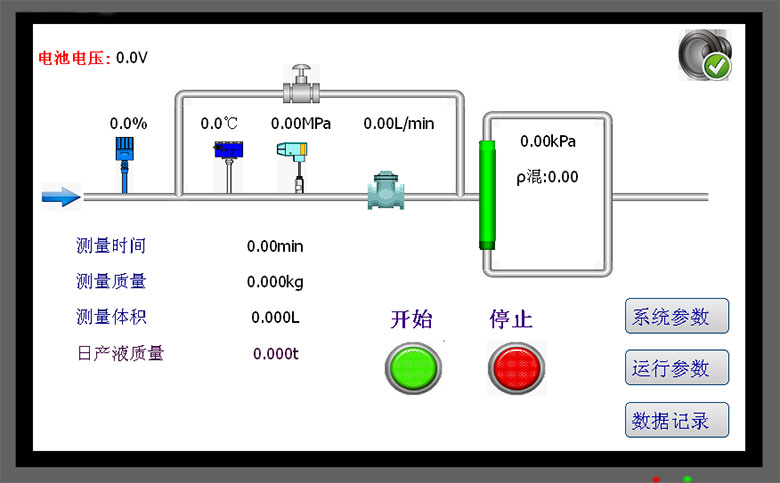

Application display of software monitoring system:

(1) System operation process interface (alarm blinks on the interface with sound)

(2) Data system operation trend display interface

(3) Display interface according to report

(4) Intelligent well selection control and application data