Digital oil production solutions

1, an overview of the

Production digitization is to install digital sensing instruments such as pressure, load, displacement, temperature and electrical parameters at the well site to transmit process detection data to the remote transmission terminal (RTU) at the well site. The RTU device is then directly uploaded to the production and operation monitoring center in the operation area through the local public communication network. Through these data, oilfield production managers can identify and judge oil production conditions, and timely take measures to ensure smooth operation of oil well production and improve oil production efficiency.

2. Solutions

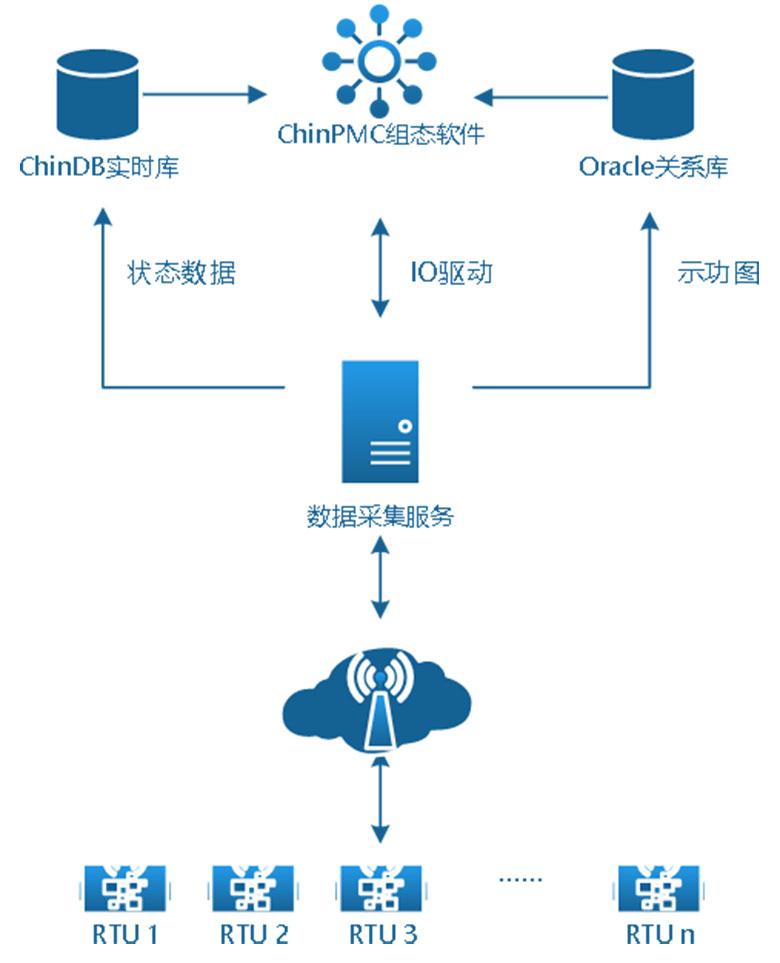

Standard RTU modules, wireless pressure transmitters, wireless temperature transmitters and wireless load transmitters are used to collect wellhead parameters and send them to the server in the information center, which stores the data and publishes it through the network. By means of digitization and networking, remote monitoring, remote transcribing and real-time display of wellhead data are realized. The overall operating architecture of the system is as follows:

(Figure 1: Overall operating architecture of the system)

Digital construction of oil production is divided into three parts: 1. Data transmission network construction; 2. Well site hardware system construction; 3. Construction of network platform of monitoring center.

2.1 Data transmission network construction

Because oilfields are often in remote areas far from towns, large-scale fiber-optic networks are expensive to build and maintain. Here we use the communication network of the local telecom operator, using DTU module to build the data remote transmission network. Its advantage is that only the telecom operators pay data traffic fees, can ensure the transmission of data, save network infrastructure and later maintenance costs.

2.2 Wellsite hardware system construction

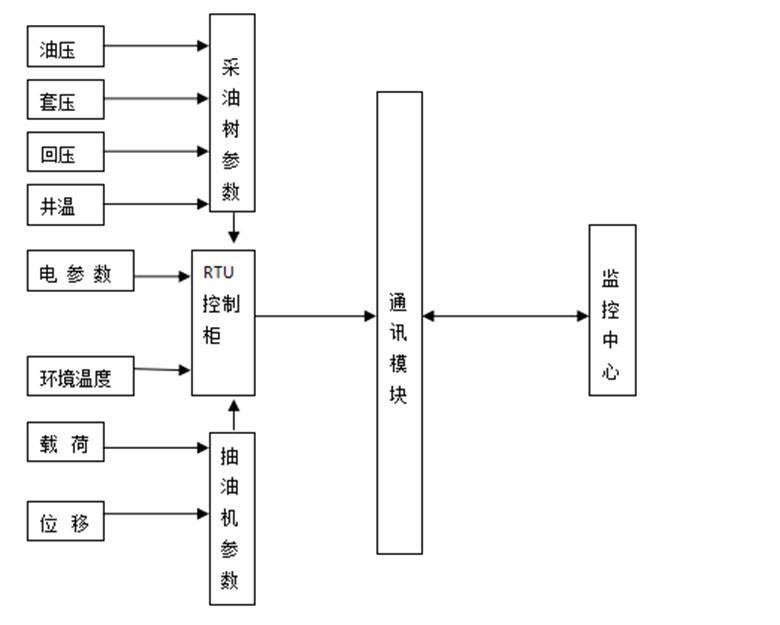

The well site data acquisition system is constructed with one set of RTU equipment and the corresponding pressure, temperature and load transmitters. The collected data, such as pressure, temperature, current and load, are uniformly processed and packaged by the RTU module, and finally transmitted to the monitoring center server through the data transmission network. Figure 3:

(Figure 3: Field hardware operation process and equipment installation diagram)

2.3 Monitoring platform construction

The remote monitoring platform system software and data server are deployed in the monitoring center to display, publish and store the data uploaded by RTU of each oil well. The monitoring platform has the following functions:

1) Real-time display of production data;

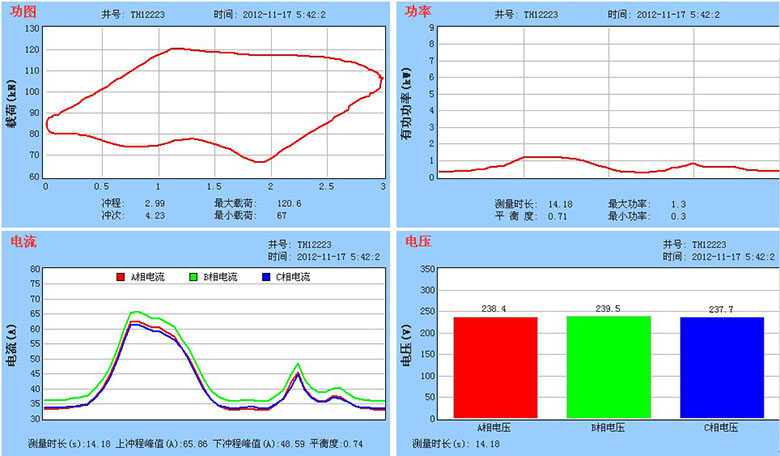

2) Detailed display of production data in the form of charts and tables;

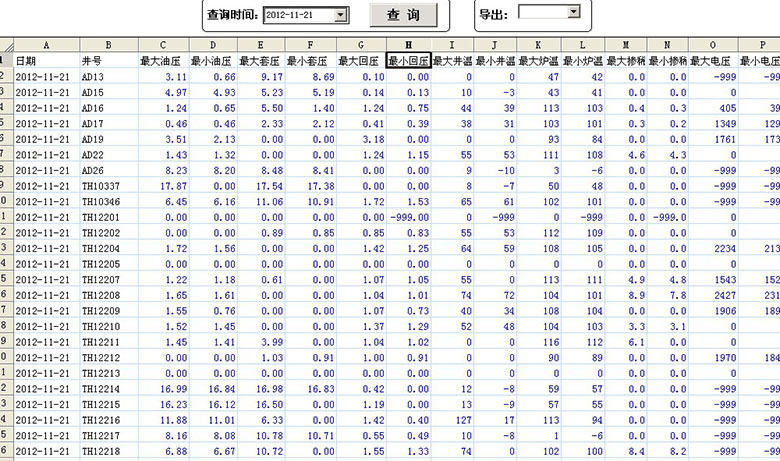

3) Production data query;

4) Input and modify basic data of oil Wells;

5) Alarm (including pressure, temperature, electric parameters, power failure alarm), alarm sound and light prompt combined with pop-up dialog box, distinguish "general alarm", "important alarm" and "emergency alarm", realize the gradual trend monitoring of alarm information, and the historical record of alarm processing can be traced;

6) Generate and download monitoring data reports (including single well and multiple well) in EXCEL format;

7) With data such as indicator diagram and electrical parameters, charts and curves query, download format is EXCEL;

8) It has the function of generating daily reports, and the report format is consistent with the source database format;

3. Field application cases

Application case in Xinjiang Sinopec Northwest Oilfield Company. As one of the upstream enterprises of Sinopec, Northwest Oilfield Company has 37 exploration blocks in Tarim Basin, covering an exploration area of 143,100 square kilometers. The oil and gas Wells under its jurisdiction are distributed in an area of 12,000 square kilometers, with large spacing and long inspection lines. The geographical environment and natural climate are harsh. It is extremely hot in summer when the temperature reaches more than 40 degrees, and it is extremely cold in winter when it reaches more than 20 degrees below zero. The construction of digital oil production greatly alleviates a series of prominent contradictions in the field production management, such as multiple Wells scattered and long battle lines, and ensures the real-time and safety of the field production management.

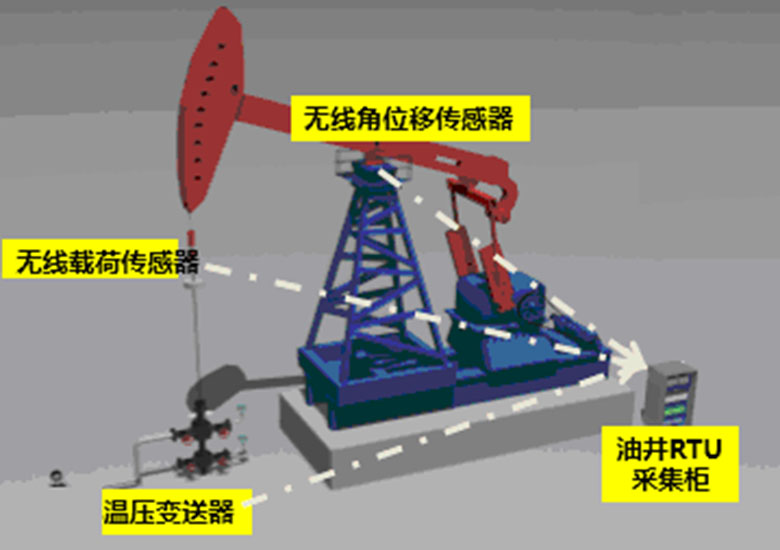

On-site hardware installation:

(Installation of tree equipment in pumping Wells)

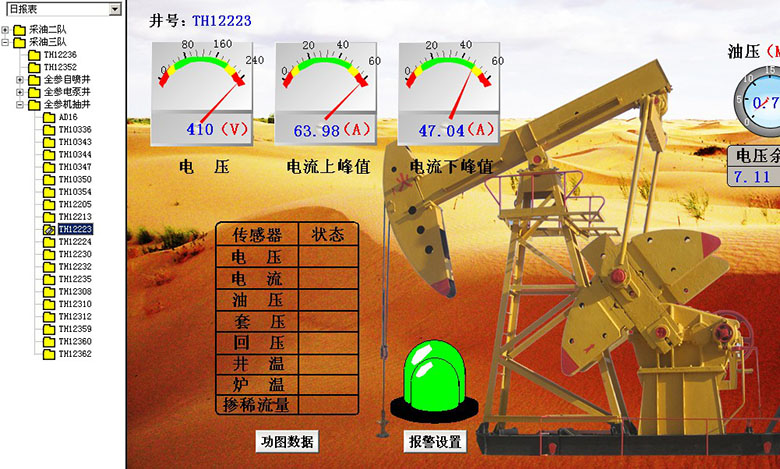

Remote monitoring platform display:

(Real-time display of pumping well data)

(Pumping well power diagram, three-phase current card)

(Daily report data summary function)